Bryn Athyn Cathedral: The Building of a Church

E. Bruce Glenn

The Timber Work

THE SIZE AND PLAN of the Cathedral did not call for a stone-vaulted roof except in the sanctuary, the chancel of the chapel, and the porches. There, especially over the sanctuary altar, where the ribbed vault is divided symbolically into twelve sections, the strong curves of the early Gothic lines form a fitting cap as they continue the lines of the walls beneath. For the nave and chancel a timber roof was regarded as both suitable and practical, offering opportunity to build with another material provided by the Lord's hand.

During Cram's first meeting with Raymond Pitcairn in the latter's studio, referred to earlier, Pitcairn pointed to the solid timber ceiling with its curved struts and rafters, and asked whether the contemplated church could not have a roof of solid timberwork. Cram's response was enthusiastic; for here was further evidence of a desire on the builders' part to avoid veneer and sham.

The challenge was twofold: to find timbers sufficiently large to span the nave and chancel, and to construct beams, rafters, and struts in such proportion and detail that the structure would grace the church's interior as well as truly support the roof. Here, on a point generally determined in that meeting during the spring of 1913, was perhaps the first indirect step toward the slow, painstaking growth of concept and organization that uniquely characterized the building of the Cathedral. In material, design, and execution, the roof was to be such that Cram predicted it would not have its equal elsewhere in America. This may be so. More important, its beauty and truthfulness, like that of the stonework, is the result of on-the-site supervision of material selection and construction; indeed, the woodworking shed at the Cathedral was the first of the several shops to be wholly organized by the builders without recourse to outside contractors.

Although it was to be two years from the church's beginnings till construction of the roof, the search for suitable timber was undertaken in the early summer of 1913, so that it might be properly seasoned before final working and placing. As with the stone for the exterior walls, the nearby countryside proved happily bountiful. Southeastern Pennsylvania had at that time perhaps the finest growth of white oak trees on the continent. To find specimens of these from which the great tie beams and struts of the roof trusses could be hewn became a personal challenge for Raymond Pitcairn. Armed with camera and accompanied by members of the family and frequently by leaders of the Bryn Athyn congregation, he traveled miles in all directions. To help find and to cut down the serene lords of the forest, he enlisted the professional aid of Isaac Ryan, a lumber dealer who had his sawmill on the banks of the Neshaminy Creek several miles north of Bryn Athyn. Like others associated with the Cathedral, Ryan caught the spirit of the undertaking, and for years made it his personal task to seek out the needed trees, conveying his discoveries to Pitcairn in letters that gave intricate directions for reaching the site over the maze of country roads, together with the announced date for the felling. More than once the search was abetted by proffers of gifts of trees from owners who were glad to contribute to the cooperative endeavor taking form at Bryn Athyn with increasing notice from the public.

The felling of these majestic trees was an awesome sight and sound; and their loss from the woods was compensated only by their destined place: to stand strong and protective, into the unmeasured future, above the singing and prayer of worship.

The largest of these trees was more than six feet in diameter at the base. The oldest, its age verified by Pitcairn and Asplundh, who counted its rings the day it was felled, was 347 years old in 1916 over a century old before the birth of Emanuel Swedenborg, half a century before the first settlement at Jamestown, and growing when Shakespeare was a small boy. This tree was cut on a farm twelve miles north of Bryn Athyn.

Out of woods and fields not many miles from Bryn Athyn, the white oaks were felled even while the church's foundations were being laid, in anticipation of the solid timber roof that years later would span the nave and chancel. Click on image for a larger version.

The trees were roughly squared at Ryan's sawmill (except for a few too big to put through the saw) and brought to the Cathedral in this form, where they lay seasoning while the walls rose nearby and the designs went forward for their hand-cutting into rafters, purlins, and the trusses to span the clerestory.

On the Quarry Road below the church hill, this log is perhaps being hauled to the site from the railroad spur at the end of the road. The horses at the other end provided a spare team for turns in pulling the heavy trunk. Click on image for a larger version.

The beauty of these solid oak trusses is in keeping with the church as a whole. Here perhaps, more than in the stonework, was temptation to excess—temptation which, if it ever occurred, was straitly rejected. Mortised and tenoned, held together entirely by pins of locust, the trusses are at once strong and simple, yet graceful in line and delicate in moulding and tracery. The great tie beams, cambered for additional strength of line, run without break from wall to wall, resting easily on the side posts that rise from the stone corbels. The struts that curve inward to lend support to the beams near the center offer a pleasing contrast while remaining in harmony with the cross timbers and the pitch of the paneled roof. Vertical emphasis is given by the solid kingpost and supporting posts that join tie beam to rafter. The whole is softened out of angularity by tracery insets of cusped arch and quatrefoil. No elongations in attempt at heightened perspective, no purposeless decoration; a very truss in name, quiet in its strength.

Again it is pleasant to note that these structures, like so much else in the Cathedral, were the product of several minds striving together. Two men from the architect's office, Donald Robb and Robert Tappan, worked out the basic design, with the latter proposing the single tie beam construction. Here too, models were brought into play, and Pitcairn, through that medium, reduced the size of the king post to bring it into harmony with the ridge timber. Nor should it be forgotten that each truss had to be of slightly individual design in proportion, since the concave refinement of the clerestory walls required that the trusses all be of different lengths.

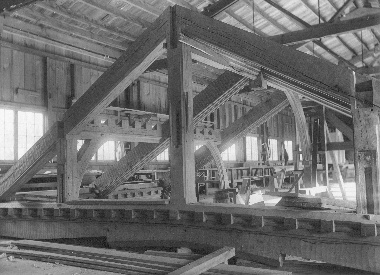

A section of roof trusses takes form in the carpenter shop, to be filled later with decorative carving. Each truss had to be designed individually because of the curve in plan of the walls on which the roof rested. Click on image for a larger version.

One more name deserves prominent mention in regard to the roof work, its design and especially its execution. Harry Bowman, a free lance building superintendent of Swiss ancestry, was chosen in 1914 to be head of the woodworking force at the Cathedral. The choice was eminently just, and Bowman remained to become superintendent of the church's building until its essential completion in 1928. A master builder, he combined a rigid sense of honesty with a real love of the work, and gained the respect of all who were associated with him, below as well as above. After Edwin Asplundh joined the army in 1917, Bowman became the strong backbone of the building operations.

With a background in carpentry, he was able to make a number of useful suggestions in the basic design of the roof truss structure. It was he who was largely responsible for the swift reconstruction—a matter of two months—of two of the big trusses and of the whole north aisle roof, following the destruction of the originals in the fire of April 1916. And when the war depleted the carpentry force, Bowman turned up one morning with a kit of tools which he had not carried for years, and took his place wholeheartedly with the joiners in the woodworking shed.

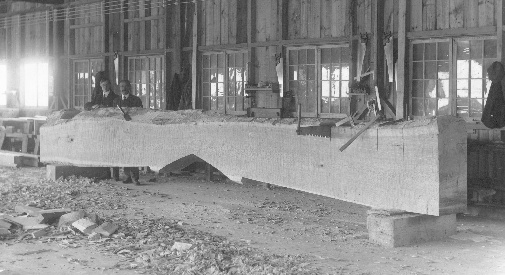

Raymond Pitcairn and Harry Bowman stand by a tie beam taking form out of a rough-hewn log. Bowman, a master carpenter, was in charge of the wood working operation, and later headed the entire building force. Click on image for a larger version.

Work with the big oak timbers high above the floor was not without its exciting moments. One incident involved the placing of a great three-ton beam into position diagonally across the tower to carry the floor of the bell deck. It had to be raised to this position by rope through an opening in the lantern ceiling from the floor of the crossing below.

This beam spans the tower diagonally and supports the bell deck above the lantern. Pitcairn and Bowman are at left. Click on image for a larger version.

For this delicate maneuver, Bowman proposed using a single rope for which he had rigged a winch that July morning in 1918. Pitcairn expressed concern, fearing the damage to pillar and floor—not to mention life—if the rope broke while the timber was nearing the lantern ceiling. Bowman pointed out that the rope was tested for twice the beam's weight, but agreed to use of a second rope from the nave.

Slowly the great timber was lifted toward its destination. Just as its middle was even with the top of the chancel arch, a loud outcry from the spectators signaled that one of the ropes had broken. While everyone watched with held breath, the broken rope was spliced, and the beam finished its journey to its final resting place. Afterward Bowman remarked to Pitcairn, "Your rope was the one that broke," adding that the fact that the timber still hung by the original rope was evidence that it was strong enough. Then, with a twinkle in his eye, he added further that what had happened indicated that one rope was not strong enough!1

The roof frame in place above the church, still to be planked with solid oak boards and sheathed in monel. Click on image for a larger version.

Of woodwork in other parts of the building little need be said here, since the ceilings in the north and south groups, of different woods and structures, will be noted in the chapters devoted to them. Doors throughout the building, as well as some floors, are of teak from India and Java. Each door is individually designed. A warm reddish-brown, cut and rubbed by hand to a satin finish, these teak doors have a beauty of their own, especially when viewed in a frame of variegated stone.

Top | Previous Chapter: The Stone Work | Next Chapter: The Metal Work | Table of Contents

Footnotes top

1 For a further description of this incident see the following: Raymond Pitcairn. Letter to Harold F. Pitcairn. 25 July 1918. Glencairn Museum Archives, Bryn Athyn, PA.